A Leading Plastic Fabrication Company

Partner with us for high quality parts, products and components.

VACUUM FORMING THERMOFORMING

CNC ROUTING & MACHINING

DRAPE MOULDING

PLASTIC LASER CUTTING

Our reputation for quality, service and price has ensured we have continued to grow our business since we were established in 1969. Our almost fifty years plastic forming and fabrication experience will help turn your requirement into a completed project.

- All forming and fabrication is carried out in house at our 46,000 square ft production unit.

- Experienced engineering staff, a dedicated CAD team and the very latest software and machinery ensure we can fabricate to the very highest standard.

- Flexible working practices and processes means that we can handle fast turnarounds and short lead times when required.

- Dedicated account managers deliver projects on time and on budget.

Our finished products are used by clients including Jaguar Land Rover, Caterpillar, JCB, TfL, NHS and many others.

Complete custom plastic fabrication services

As a leading plastic fabrication company we provide a complete range of process and services:

- Vacuum forming, oven transfer moulding, drape forming and press moulding manufacturing processes.

- Assembly, local bending, bonding, gluing, mechanical testing and insulation

- Prototypes and one-offs, short runs and large volume production runs

- Advice on design and manufacture

- Extensive production space and warehousing facility

- Assembly and collation teams and distribution service that delivers across the UK and Europe

- Incorporating wood, metal and other materials

We can manage the complete production process from design to delivery, if required. We provide in-house branding, printing and signage capability to add the finishing touches, packaging and labelling to your moulding and/or fabrication project.

Specialist services include: industrial moulding; 3, 4 & 5 axis CNC routing services; thermoplastic moulding; drape moulding, and blow moulding.

White label service

We are happy to work as a sub-contractor across many projects and have experience working as a ‘silent partner’ for O.E.Ms, manufacturers, design and retail agencies, shopfitters and many others. We don’t subcontract fabrication services so we are able to keep complete control of the manufacturing process. Relax, you – and your clients – are in safe, expert hands.

Investment in the latest plastic fabrication technology

We have a rolling programme of investment that has seen us introduce some leading edge cutting, moulding and machining technology – often for the first time in the UK. Our investment helps us remain competitive in a global market and supports UK jobs. For customers the benefits are clear: increased workflow and decreased wastage, reduced production times, improved quality, and extend fabrication services across a range of plastics and substrates.

Plastic Fabrication Quick Quote Form

SUSTAINABLE SOLUTIONS

We take our commitment to the environment and to ethical trading seriously. For details of our ISO 9001 accreditation, environmental policy and supply chain credentials go here.

OEM SERVICES

We provide OEM and OEM Automotive services to a range of manufacturers and suppliers. Find our how we can help your organisation improve reliability and save costs today.

DESIGN & CAD

Inhouse design and CAD services will help ensure the maximum effectiveness of the part, product or component at the lowest possible cost. Our unbeatable material credibility and manufacturing expertise will help deliver the right results first time every time

Find out more about our recent plastic fabrication projects

Partner with a full service plastic fabrication company

We offer a UK-wide plastic fabrication service. As well as offering a comprehensive range of process our added-value services will ensure the successful completion of your project. Inhouse plastic fabrication services using sector-leading equipment include vacuum forming, CNC routing & milling, laser cutting & profiling, drape moulding and line bending. Most finishing is also completed inhouse such as polishing, cementing and taping.

Our plastic fabrication UK additional services include design & CAD, assembly and collation. With an established logistics team and large warehousing facility we can store completed products until call-off and then distribute as required.

With over 50 years plastic manufacturing expertise and unparalleled material and process understanding our aim is deliver a high quality cost-effective solution to your needs.

Wrights Plastics has solidified its position as a leading and reputable plastic fabrication company through years of consistent innovation, impeccable craftsmanship, and unparalleled customer satisfaction.

Wrights Plastics offers high-quality and bespoke plastic solutions. Their team of skilled designers, CAD specialists & engineers employs state-of-the-art technology to transform raw materials into precision-engineered products that meet the most demanding specifications. The company’s dedication to quality control and adherence to industry standards ensure that each product leaving their facility is of the utmost excellence.

What truly sets Wrights Plastics apart is its customer-centric approach. We collaborate closely with clients from various industries, understanding their unique requirements and turning concepts into reality. This personalised service, combined with efficient project management, has earned them a reputation as a trustworthy partner in bringing ideas to life.

In addition to our technical expertise, Wrights Plastics is also recognised for its sustainable practices. The company places a strong emphasis on eco-friendly materials and production processes, contributing positively to both the environment and the clients they serve.

WHAT IS PLASTIC FABRICATION?

Plastic fabrication is the process of manipulating and shaping raw plastic materials into finished plastic products or components. The raw materials used in plastic fabrication are known as polymers, which are large molecules composed of repeating subunits called monomers. These polymers can be synthetic or naturally occurring and possess a wide range of properties, making them suitable for various applications.

The process of plastic fabrication involves several techniques, each designed to achieve specific results based on the desired product. These techniques include:

1. Plastic Extrusion: Plastic extrusion is a popular method where raw plastic materials are melted and forced through a die to form continuous profiles. The extruded plastic can take the shape of pipes, tubes, sheets, and various custom profiles, making it a versatile process used in construction, packaging, and automotive industries.

2. Injection Molding: Injection molding is a widely-used technique that involves injecting molten plastic into a mold cavity, where it cools and solidifies to form the desired shape. This method is ideal for mass-producing intricate and complex parts, such as bottle caps, automotive components, and household items.

3. Thermoforming: Thermoforming employs heat to soften plastic sheets, which are then shaped over a mold using pressure or vacuum. It is commonly used to create packaging materials, disposable cups, and trays.

4. CNC Machining: Computer Numerical Control CNC routing involves using precision machinery to cut, drill, and shape plastic materials based on computer-generated designs. This method is ideal for creating custom and high-precision parts in industries like aerospace and electronics.

5. Welding and Joining: Plastic fabrication may also involve welding and joining techniques to assemble various plastic parts or components. Common methods include ultrasonic welding, solvent bonding, and hot gas welding.

WHAT WE FABRICATE

As a leading plastic fabrication company for over 50yrs we make a huge range of plastic parts, products and components across many secotrs.

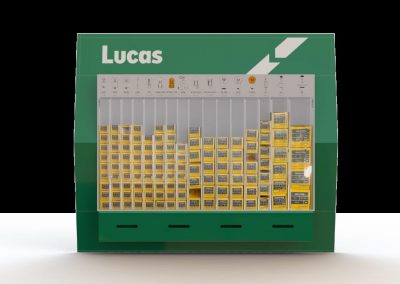

1. Point of Sale: We make a huge range of retail display, POS and POP products – from bespoke one-offs to large volume stands, racks, FSDUs, CTUs, shelf management and more.

2. Automotive: For the automotive industry, we make components, screens, interior parts and mouldings, covers, trays etc

3. Electronics: The electronics industry heavily relies on plastic fabrication to produce casings, connectors, and insulating components for various devices and equipment.

4. Street Furniture & Traffic Management: We fabricate covers, backboards, lenses, shrouds, baffles etc.

5. Medical Devices: Plastic fabrication is crucial in the production of medical devices, equipment, and packaging. Its biocompatibility and ease of sterilization make it suitable for a wide range of medical applications.

Conclusion:

Plastic fabrication is a fascinating and indispensable process that has revolutionized modern manufacturing. From its early origins to the sophisticated methods employed today, plastic fabrication continues to be a driving force behind innovation and product development across various industries. The ability to transform polymers into valuable products and components has cemented plastic fabrication as a cornerstone of modern society, enabling us to enjoy the convenience, safety, and efficiency of countless plastic-made items in our daily lives.