our first project for the Marks & Spencer proved a challenge that we met with exceptional success.

With a twelve week lead time from order to roll-out to 25 prime stores, our first project for the nation’s favourite retailer certainly proved a challenge that we met with exceptional success.

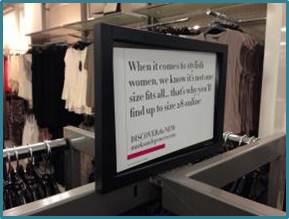

Following a successful tender to produce the signage required for M&S’s rebranded Womenswear Collection, we developed new manufacturing processes and value-added services in order to ensure we met the client’s demanding delivery timetable, budget and their Plan A standards of sustainability.

Initially we provided prototypes of all the required types of display panels and fittings. We added machinery to allow us to create wooden frames. We worked with a huge range of substrates including wood, dibond, PETG, metal and acrylic.

Innovative processes including direct print onto dibond for increased quality and longevity, improved laser cut lettering and enhanced adhesive techniques.

As a world leader in sustainable retail, Marks & Spencer have stringent standards for their suppliers. On this project, for example

- all wood required FSC certification

- the dibond used was manufactured from recycled material

- only Green Cast acrylic was used – 100% recycled and 100% recyclable