Drape Moulding & Press Moulding

A heritage of manufacturing skills matched with the very latest equipment

LARGE PLANT LIST

IS0 9001

OVER 50YRS' EXPERTISE

SPECIALIST TEAMS

INHOUSE FINISHING

Flexible Solutions For Your Injection Moulding Needs

With over 50 years’ experience we believe we can provide the most effective manufacturing option for a wide range of parts, products and components.

Our investment in cutting-edge machinery, our knowledge of materials and our aim to work as sustainably as possible helps us offer clients the most efficient solution for their project. Our design team can help value-engineer the most effective design, and everything is carried out under one roof – as well as giving extra piece of mind it also lowers carbon footprint, reduces costs and turnaround.

We can help with large or small volume production including rapid plastic prototyping, as well as simple to more complex products.

For POS/POP retail display projects we can provide sector-leading design and manufacturing services as well as assembly, collation and distribution services.

For industrial parts and products we use our extensive manufacturing experience to deliver cost-effective solutions using the latest in super-efficient low-energy plant & expert production teams,

Press Moulding

Our press moulding services deliver high quality products thanks to our experienced teams and range of moulding ovens. With a range of leading-edge kit we can finish to an unbeatable standard. We are happy to advise on material, design and production methods to deliver the most cost-effective solution to your press moulding needs.

Acrylic sheets are heated in our moulding ovens set at between 1350°C to 1750°C (275°F to 350°F) then placed over a mould shape and pressed into shape. The heat and pressure force the materials into all areas of the mould. The heat and pressure cycle of the process will harden the material and then it can be removed. Press moulding offers the ability to create very complex parts, and also allows for longer fibres than plastic injection moulding, resulting in stronger and stiffer materials.

With over 50 years’ acrylic fabrication experience we have extensive knowledge of oven transfer moulding processes including drape and press moulding helping us deliver high quality cost-effective parts and products in low to high volumes.

Drape Moulding

With relatively inexpensive tooling, drape moulding is ideal for low volume projects but we also have the capacity to manufacture at high volume when required. it is an ideal way to produce curved or shaped parts and products – our team will always help you choose the most effective fabrication process.

Our experienced team and large capacity equipment means we can produce a wide range of drape moulded products in low and high volumes. We can drape mould up to 2.5m so there are very few projects that we cannot undertake.

We currently manufacture a range of products using drape moulding process including

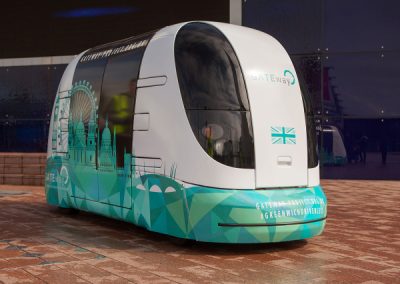

- boat screens, car screens for our the automotive sector

- curved displays for Point of Sale displays

- curved or shaped letters, logos and complete signs for maximum impact

Our capacity includes

- LARGE MOULDING OVEN

- SMALL MOULDING OVEN

Complete The Quick Quote Form

INHOUSE DESIGN & CAD

Turning your idea into a workable design with effective CAD is part of the service. Our expert team bring their experience to every project to deliver cost-effective solutions.

SUSTAINABLE SOLUTIONS

Our investment in cutting edge machinery is just part of our ambition plan to lower energy use, reduce material waste and lower our carbon footprint. You can find out more about our sustainability plans here

APPLICATIONS EXPERTISE. MATERIAL CREDIBILITY

In plain English, we know our stuff. Understanding the strengths and limits of a whole range of plastics and maximisng the effectiveness of our huge plant range ensures we deliver the right solution first time every time – great for the customer, good for the planet.

Find out more about our recent press moulding and drape moulding projects