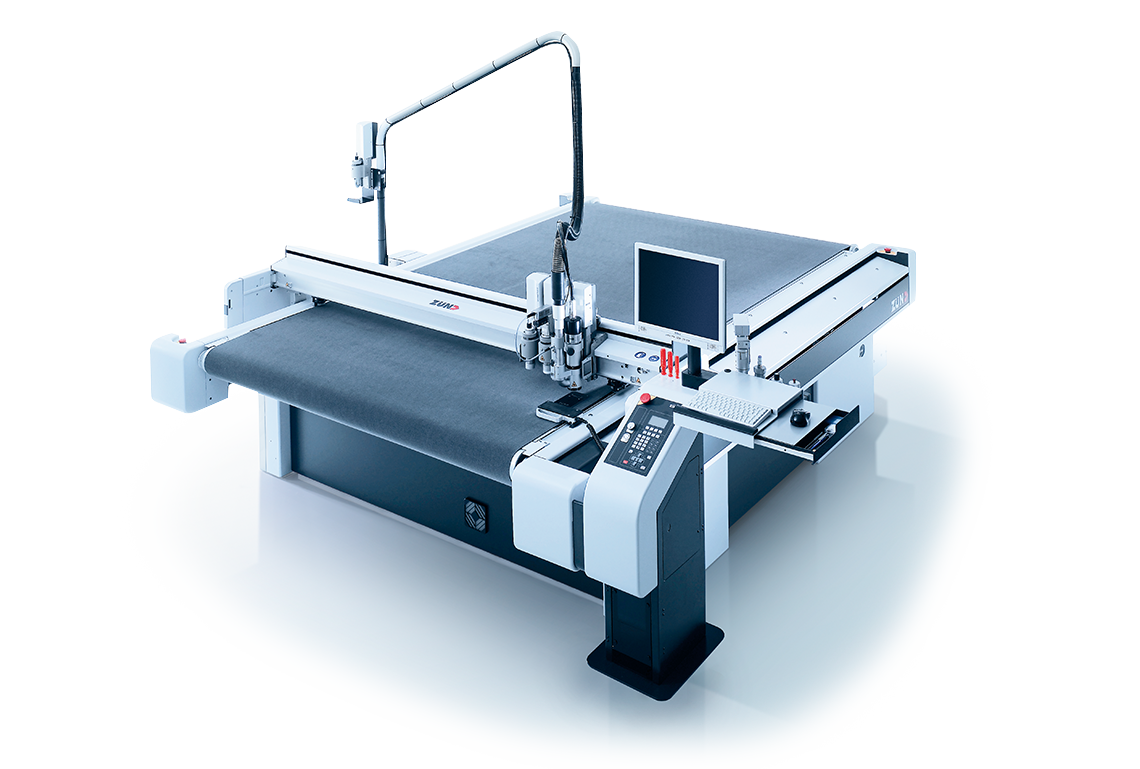

Investment in Zünd G3 Cutter Enhances Precision Plastic Fabrication

To support growing demand for accurate, high-speed plastic cutting, Wrights Plastics invested in a Zünd G3 digital cutter. This advanced cutting system allows us to process a wide range of materials with outstanding precision — reducing waste and increasing efficiency.

The G3 is used extensively in our plastic fabrication and retail display projects, especially where speed and detail are critical. Its multi-tool configuration supports the cutting, routing, and scoring of materials like acrylic, PETG, and composite sheets.

This investment strengthens our in-house production capabilities and ensures we continue to deliver high-quality, cost-effective solutions across sectors such as automotive, retail, and industrial applications.