A recent report on the global market for automotive plastics predicts growth to $30billion by 2026, driven by global pressure to reduce emissions and improve fuel efficiency – and we have seen our work in this sector grow in recent years.

The report suggests growth of Compound Annual Growth Rate (CAGR) of over 7% as international markets bounce back after the impact of Covid19.

One of the main drivers for growth the report suggests is the adoption of lightweight materials due to stringent emission and fuel economy regulations. It states:

“Several governments across the globe have introduced stringent emission and fuel economy regulations for vehicles. These regulations have compelled automotive OEMs to increase the use of lightweight materials such as plastics. Advanced plastics materials help increase the fuel economy of a vehicle while ensuring safety and performance. A 10% reduction in vehicle mass can improve fuel economy by 6 to 8%. The use of plastics reduces the consumption of fuel in a vehicle because less weight takes less energy at the time of acceleration. Carbon emission in passenger cars can be reduced by using greenhouse gas (GHG) reduction technologies, such as adjustment in valve timing, turbocharging, aerodynamic designing, and introduction of hybrid, plug-in hybrid, and fuel cell systems in automobiles. However, these technologies require modifications in engine design, powertrain systems, and power systems that involve high degree of complexities. Therefore, advanced plastic materials are being extensively used for the significant reduction of carbon emissions, which is comparatively reasonable than the above mentioned technologies.”

Growth of Electric Vehicle Markets

A further boost to the market for plastic parts and components in the sector is the growth of Electric Vehicles development.

“The introduction of EVs has resulted in a technological revolution in the automotive industry. These vehicles have superior performance to their internal combustion counterparts. Factors such as increase in environmental awareness, government support and incentives, and investments by OEMs have paved the way for EVs. Leading automotive players such as Volkswagen. BMW, Tesla Motors. Ford, General Motors and Toyota have ventured into the electric vehicle segment. EVs are more efficient, energy independent, and better than gas alternatives. Since EVs have low-power engines, they use lightweight materials that drive the engine’s pulling capacity. Therefore, the increasing demand for EVs provides an opportunity for the growth of the automotive plastics market.”

Our growth in the automotive sector

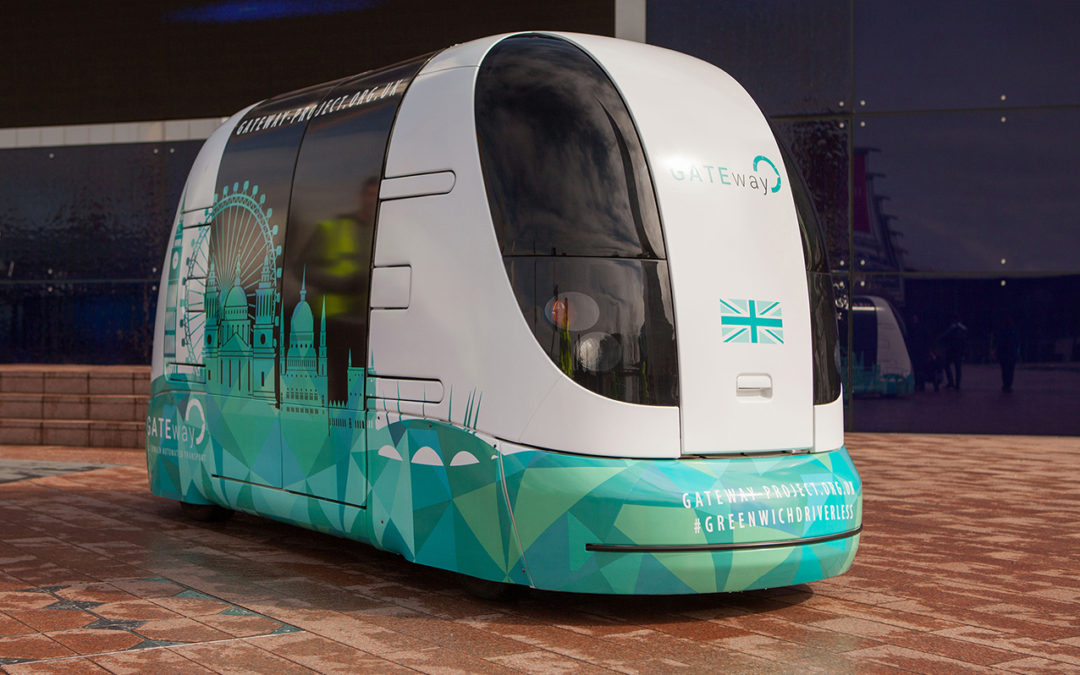

We have an established record of delivering high quality plastics parts and components for a range of vehicles using several of our core skills such as vacuum forming, CNC milling and laser cut plastics. Clients include Jaguar Land Rover and The Morgan Car Company. Increasingly however the work we do in the sector is diversifying. As well as increased demand for leisure vehicles and motorhome conversions, we are also seeing more projects in the EV, AV and driverless sectors.

One ‘driver’ for our growth in this sector is quality, and a recent example of this is our gaining ECE R43 safety certification for screens manufactured for The Morgan Car Company. This demonstrated our ability to manufacture to the highest specification and beyond.

Find out more about our work in the automotive sector.