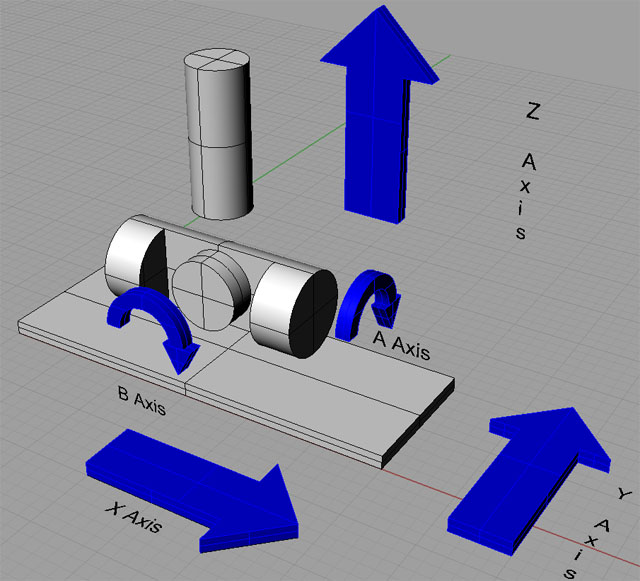

The term “5-axis” refers to the number of directions in which the cutting tool can move. On a 5-axis CNC, the cutting tool moves across the X, Y and Z linear axes as well as rotates on the A and B axes to approach the material from any direction. In other words, you can process five sides of a part in a single setup.

What are the benefits of 5-axis CNC?

The main benefit is the ability to manufacture more complex products from a single set up. This helps manufacturers save time in both the set up & the completion of the process. Saving time usually means lower costs, and should also mean reduced environmental impact of the manufacturing process.

Shortened lead times support efficient ‘just in time’ manufacturing.

5axis CNC can also offer greater accuracy with a reduced chance of the part failing due to it being moved across multiple workstations or undergoing multiple processes.

5axis CNC routing or machining will help achieve a superior surface finishes and overall better quality.

How to choose your 5-axis CNC service

Remember the quality of the product that has been manufactured using this process depends not just upon the process but the machinery used and the team in charge. Expertise in the process, knowledge in correctly setting up the job and quality control during manufacturing is critical elements to a successful outcome. Using the latest in 5-axis CNC machinery will maximise the quality, speed and efficiency of the project.

Wrights Plastics has over 50 year’s expertise in precision CNC routing and machining. Our investment in the latest kit and technology has helped us increase efficiency and speed of production as well as reduce waste and energy-use. Our dedicated team will work with you throughout the whole process – from creating CAD files for best set-up to despatch of the production run.

Recent Comments