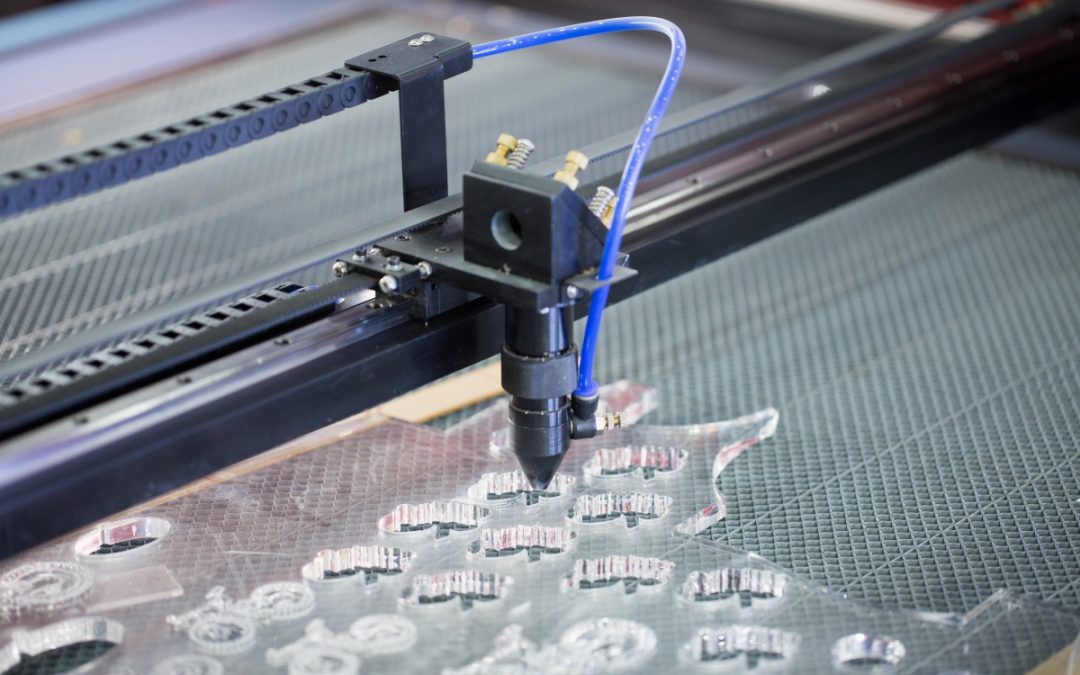

With over 50 yrs CNC expertise and some of the best kit around we can deliver high quality precision CNC’d parts – from low volume plastic prototypes to complex projects.

What is CNC?

CNC (computer numerical control) machining is a manufacturing process where a programmed computer software directs the machinery and tools. This can be used to automate a range of manufacturing processes such as routing, milling, and laser cutting plastics and other materials. Instructions are fed into the CNC machine through a CAD file and transposed into a precise set of sequential instructions.

The reference to axes is used to describe CNC machines which operate along multiple axis points. CNC machining is the process of removing material from a workpiece until the desired shape is reached. CNC machines have at least 3 axes and operate along an XYZ plane: X axis (vertical), Y axis (horizontal), and a Z axis (depth).

The number of axes on a CNC machine determines the type of work it can do, the level of detail, and the locations it can manipulate.

3 Axis CNC

3 axis CNC machining means the workpiece remains in the same position while the cutting tool operates along the XYZ plane to trim away material. This is suitable for parts that don’t require a lot of depth and detailing.

4 Axis CNC

4 axis CNC machining implies that a workpiece is processed in the same way it would be with a 3 axis machine, but has an additional rotary movement around the X axis, which is named the A axis. This rotation allows the workpiece to be cut around the B axis. This method is beneficial when holes or cuts need to be made on the sides of a workpiece. The addition of a fourth axis (A axis) allows a workpiece to be automatically flipped over, so the machine can remove material from both sides. 4 axis machining is multifunctional and can be used for engraving and intermittent cutting.

The 4th axis denotes the inclusion of an A axis (rotation around the X axis), and the 5th axis denotes the B axis (rotation around the Y axis).

5 Axis CNC

Most often used for the most complex parts and components, 5 Axis machining implies that a workpiece can be automatically manipulated from five sides at one time. In addition to automatic movements along the X, Y, and Z axes, 5 axis CNC machines can select two of the three rotational axes (A,B,C) to use. The A, B, and C axes perform a 180° rotation around the X, Y, and Z axes, correspondingly. This complexity requires 5 axis greater CNC programming expertise and preparation time to accommodate complex rotatory movement, but allows one workpiece to be worked on all five sides during one operation to help reduce time on the machine, thereby lowering costs and also helping to reduce costs and energy use. 5 axis machining is most used to maximise component accuracy, increase productivity & finish quality, cut more intricate details and machine complex shapes.

AXES MOVEMENTS

X axis – left to right

Y axis – front to back

Z axis – up and down

A axis – 180° rotation around the X axis

B axis – 180° rotation around the Y axis

C axis – 180° rotation around the Z axis

TYPES OF CNC MACHINES

3 Axis – X, Y, and Z axes

4 Axis – X, Y, Z, and A axes

5 Axis – X, Y, and Z axes and two out A, B, and C axes